High Precision High Speed Machine CK6156

Core: Max. swing over bed Φ560 mm, over cross slide Φ350 mm; center distance 1000-3000 mm

Spindle: Speed 45-1600 rpm, bore Φ82 mm; motor power 11 kW

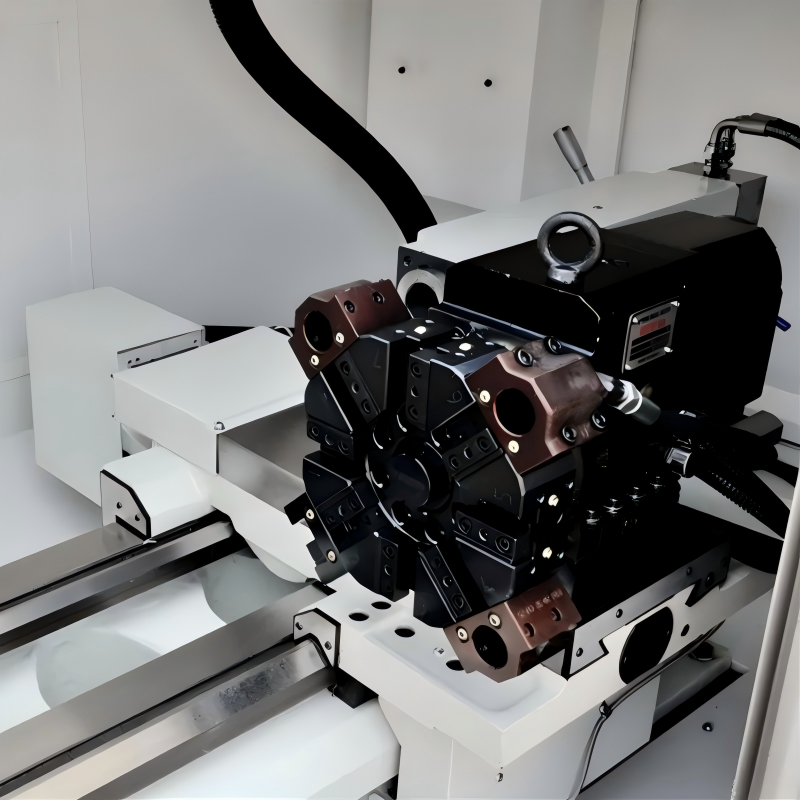

Feed/Tooling: X/Z rapid traverse 6000/8000 mm/min; 4-station turret, tool 25×25 mm

Accuracy: Machining IT6; positioning accuracy (X/Z) ≤0.02/≤0.03 mm

Weight/Dimensions: Gross weight 2600-4250 kg; packed size 3200-5200×1600×1700 mm

- Overview

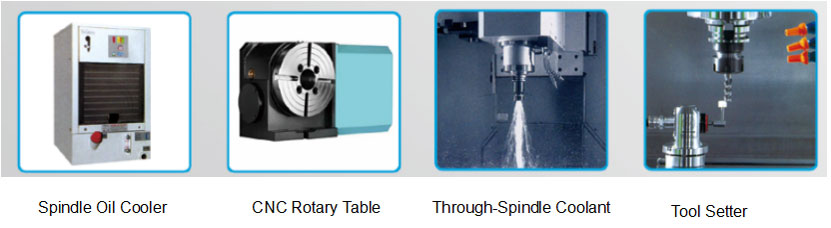

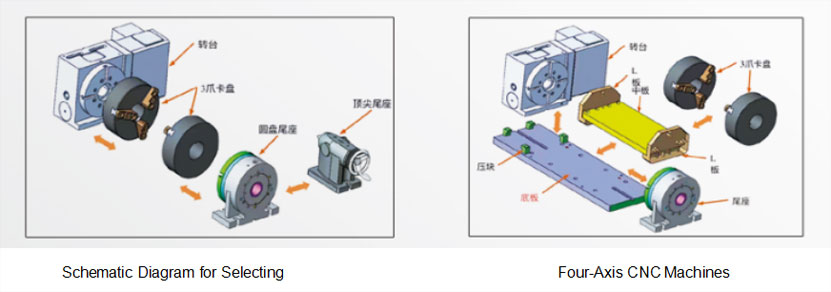

- Recommended Products

Product Parameters:

SPECIFICATIONS | Unit | CK6150×1000/1500/2000/3000 |

Max.swing over bed | mm | φ500 |

X-axis rail span | mm | 210 |

Z-axis rail span | mm | 400 |

Max.swing over cross slide | mm | φ250 |

Distance between centers | mm | 1000/1500/2000/3000 |

Maximum turning length | mm | 850/1350/1850/2850 |

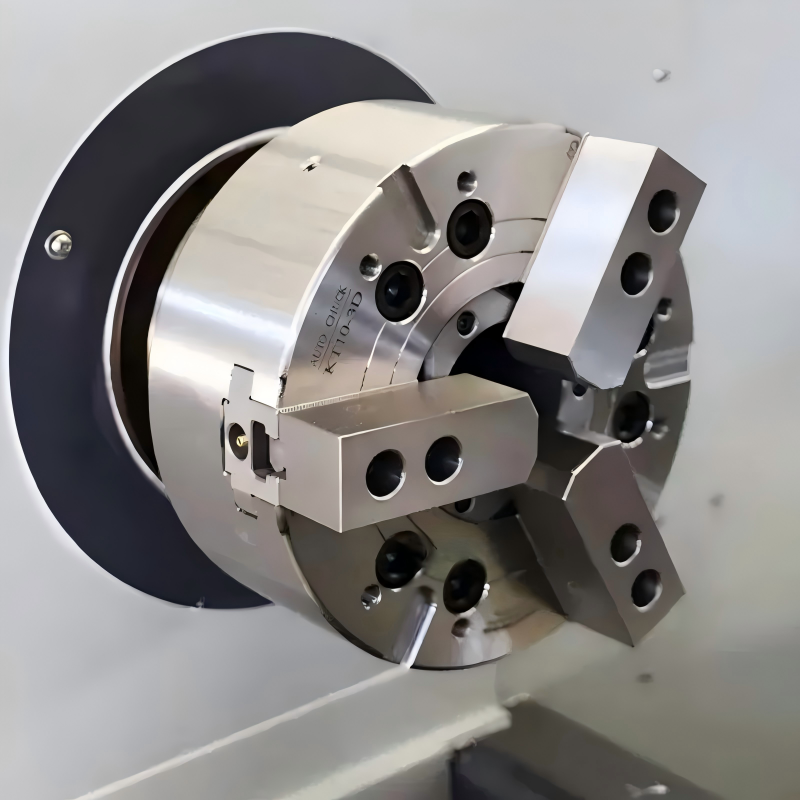

Spindle bore | mm | φ82(Optional φ130) |

Bar diameter | mm | Φ80(Φ128) |

Hollow chuck tie rod through hole | mm | Φ65(Φ115) |

Spindle nose type | A2-8/A2-11 | |

Chuck size | mm | Ordinaryφ250(Φ380) |

Spindle bore taper | No | Metric 90,1:20 |

Spindle speed steps | rpm | 1800(800) |

Tailstock quill diameter | mm | φ75 |

Tailstock quill taper | No | MT5 |

Tailstock quill travel | mm | 150 |

Tailstock configuration | Ordinary hand-crank | |

Number of electric tool holder positions | 4 Optional 6-statin α 8-staion | |

Tool shank size | mm | 25×25(4 station) |

X axis | mm | FDC2506-P3 |

Z axis | mm | FDC4008-P3 |

X/Z axis rapid traverse | m/min | 6/8 |

X axis travel | mm | 280 |

Minimum setting unit | mm | 0.001 |

Main motor power | KW | 7.5 Optional 11 |

Total power capacity | KW | 13 |

Net weight | Kg | 2700/3100/3500/4300 |

Dimensions(L×W×H) | mm | 2650/3250/3750/4750×1700×1820 |

Processing Cases:

Production Workshop:

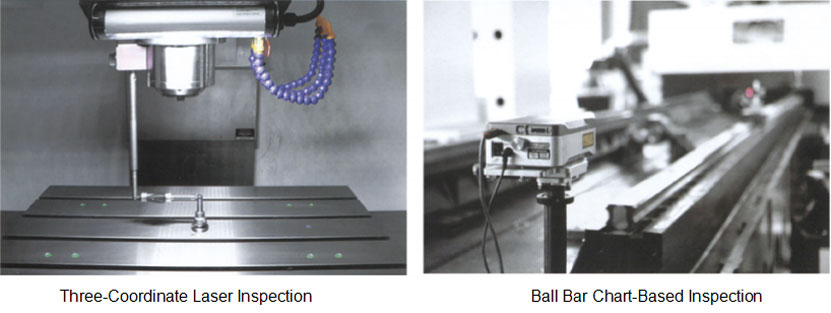

Our production facility is a modern smart manufacturing workshop integrating precision machining, specialized assembly and debugging, stringent quality control, and efficient logistics, with an annual production capacity exceeding 800 machine tools. The workshop is divided into five functional zones: Precision Machining, Assembly and Debugging, Welding and Structural Manufacturing, Quality Inspection, and Spare Parts Storage & Logistics. It is equipped with advanced machinery including five-axis gantry machining centers, coordinate measuring machines, and robotic welding arms. Standardized management processes are implemented, encompassing 5S workplace management and the ISO 14001 Environmental Management System.

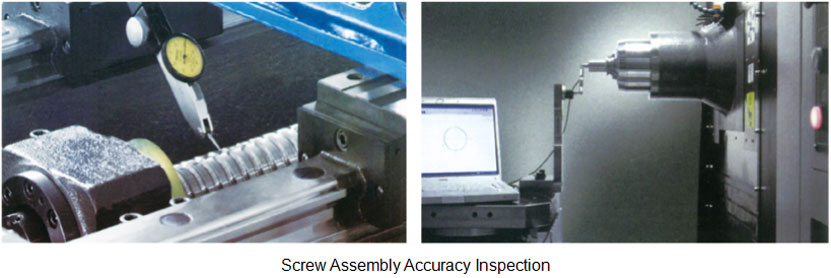

All processes adhere to high-precision standards (e.g., IT5 machining accuracy, Ra 0.4μm surface roughness for critical components) and rigorous quality inspection procedures (all parts undergo three rounds of inspection). The logistics zone

adjacent to Qingdao Port ensures efficient maritime delivery to global customers. This layout not only guarantees stable product quality and sufficient production capacity but also demonstrates our firm commitment as a modern manufacturing enterprise to clean production and social responsibility.

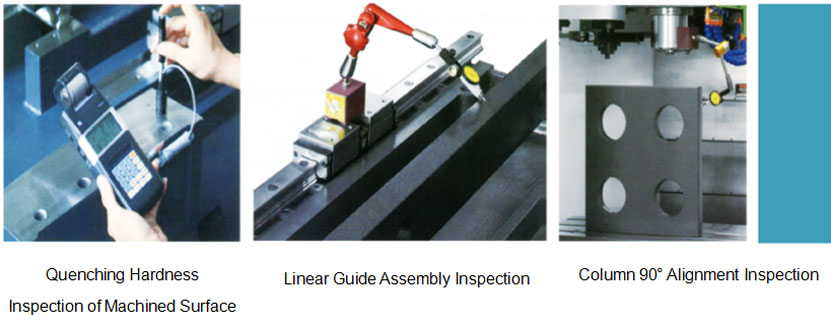

Multi-Layer Process Inspection:

Packing and Shipping:

After production is completed, our equipment is packed in customized solid wood fumigated crates, ensuring a tight, secure, and reliable package. Shock-absorbing foam and steel reinforcements are used inside to control any movement of the

machine’s core components to within millimeter-level precision during transportation.

From packaging and loading to warehousing and shipment, we extend the same strict standards we apply to machining accuracy to every stage of logistics. Because the true value of a machine tool lies not only in its processing capability, but also in

our commitment to “zero-loss” delivery from shipment to commissioning.

Choosing us means choosing safe, reliable transportation and full responsibility at every step of the logistics process.

FAQ

Q: Why choose us?

A. We are a manufacturer; we have manufactured machine tools for over 20 years.

B. Reliable Quality Assurance System;

C. Cutting-Edge Computer-Controlled CNC Machines;

D. Bespoke Solutions from Highly Experienced Specialists;

E. Customization and OEM Available for Specific Application;

F. Extensive Inventory of Spare Parts and Accessories;

G. Well-Developed Worldwide Marketing Network;

H. Efficient After-Sale Service System

Q: What is your payment term?

A: 30% TT deposit, 70% balance T/T before shipping.

Q: Can we print our logo on your products?

A: Yes, we offer OEM/ODM service, and we support the customized logo, size, package, etc.

Q: What is your main market?

A: North America, South America, Eastern Europe, Western Europe, Southeast Asia, Africa, Oceania, the Middle East, Eastern Asia,

Q: Can I get professional guidance?

A: Yes, the professional guidance can be provided.