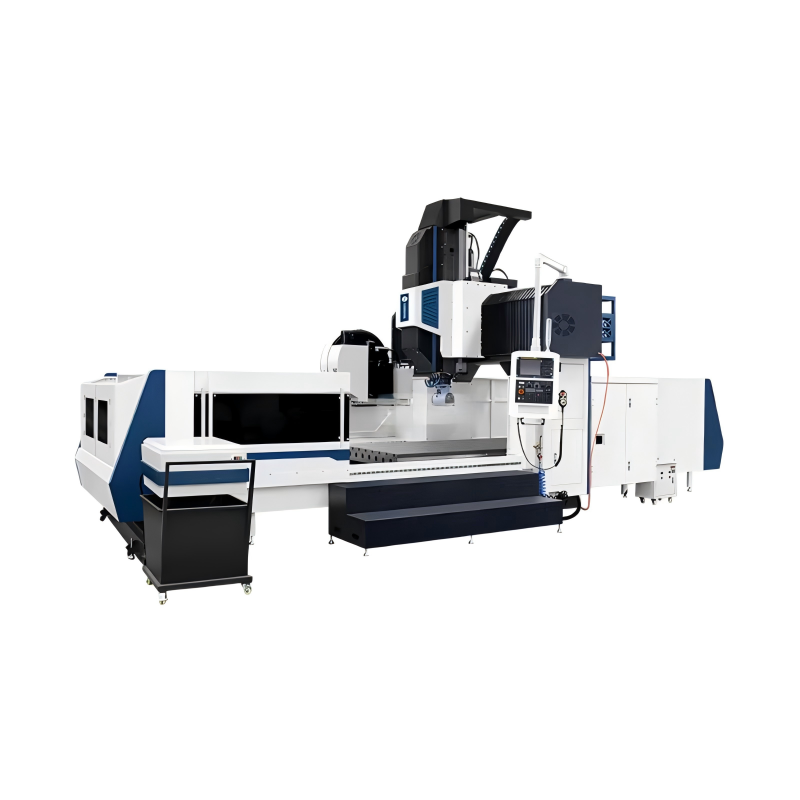

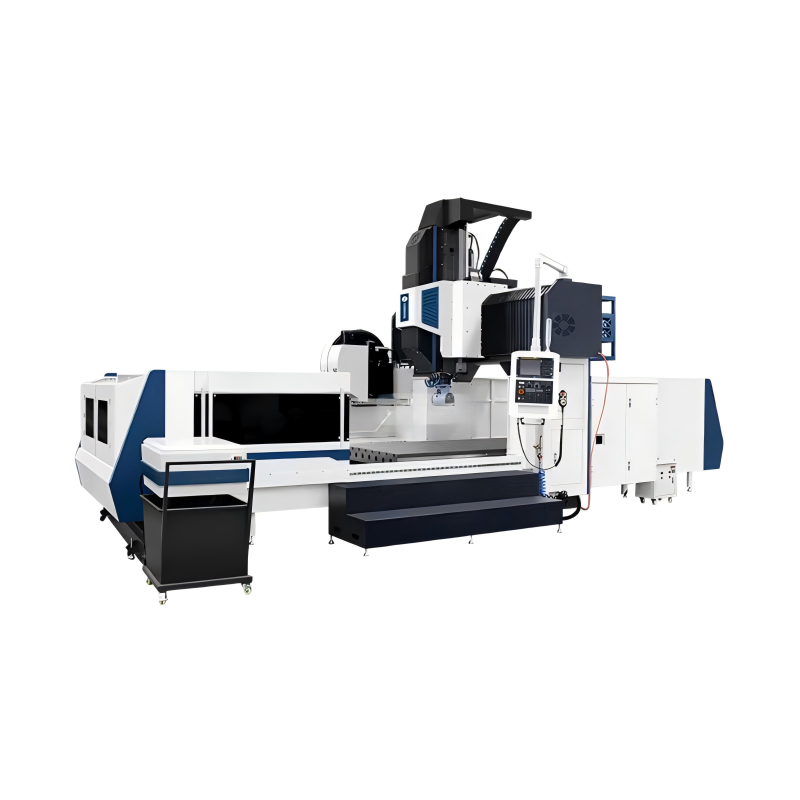

Industrial Fixed Beam CNC Large-Format Machine Center GMC-3020

Travel: X-axis 3000mm, Y-axis 2000mm, Z-axis 850mm

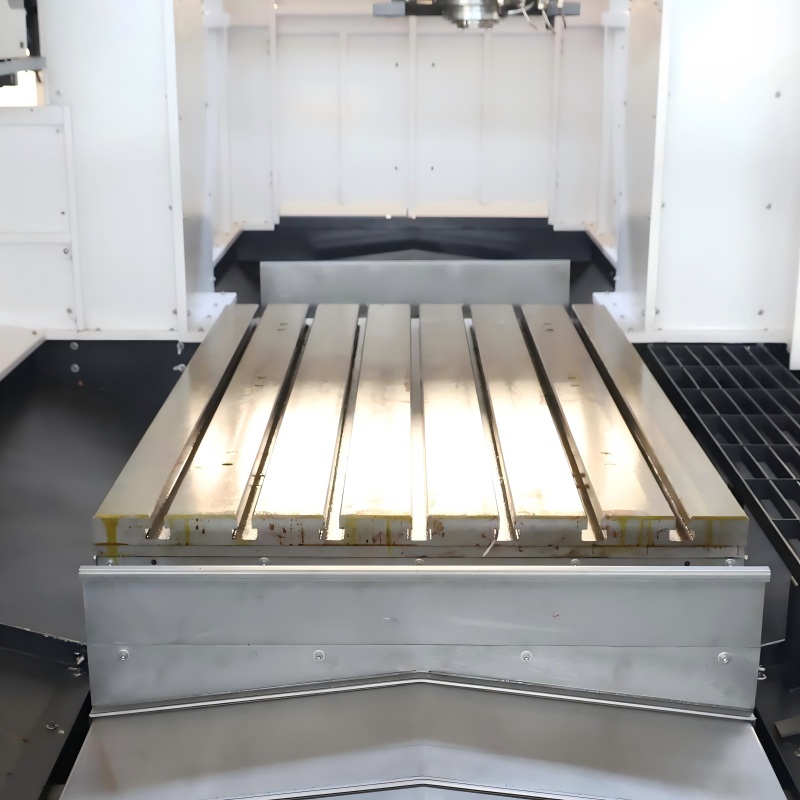

Work Table: Dimensions 3000×1700mm, Maximum Load Capacity 6000kg

Spindle: Speed 6000 rpm, Power 18.5/22 kW, Taper BT50

Travel Speed: XYZ axes rapid traverse 10/10.8 m/min

Equipment Dimensions: Length 7500 mm, Width 4600 mm, Height 4500 mm, Weight 28000 kg

- Overview

- Recommended Products

Product Parameters

MachineType | Unit | GMC3020 |

X axis travel | mm | 3000 |

Y axis travel | mm | 2000 |

Z axis travel | mm | 850 |

Distance from spindle nose to worktable surface | mm | 200-1050 |

Gantry door width | mm | 2000 |

Worktable | ||

Table size(X axis) | mm | 3000 |

Table size(Y axis) | mm | 1700 |

T-slot | mm | 9-22-185 |

Max.table loading capacity | kg | 6000 |

Spindle | ||

Spindle speed(belt type) | rpm | 6000 |

Spindle motor | kW | 18.5/22 |

Spindle bore taper | BT50 | |

Feed system | ||

three axis motors | X-axis Reducer, YZ Direct-drive Type | |

XYZ axis rapid movement | m/min | 10.10.8 |

Tool magazine | ||

Tool Magazine Capacity | pcs | 24-position Arm-type |

Machine size | ||

Machine length | mm | 7500 |

Machine width | mm | 4600 |

Machine height | mm | 4500 |

Machine weight | kg | 28000 |

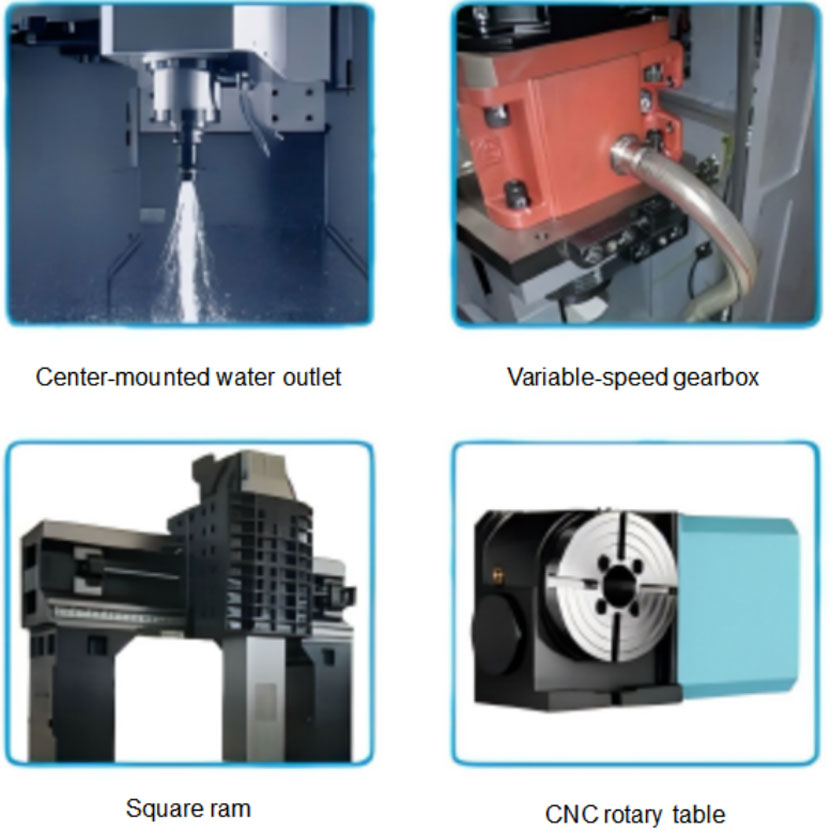

Key Components

Optional Configuration

Standard Configuration

KND 2000MF

BT50 Spindle

Dual Helical Chip Conveyor

Three-Axis Roller

Chain-Plate Chip Conveyor

24-Tool Disc Tool Magazin

Optional Configuration

Imported Variable Speed Gearbox

Spindle Center Coolant Supply

Spindle Oil Cooler

CNC Tool Post

Various Angle Milling Heads

Full-Chain Tool Magazine

Processing Cases

The gantry machining series accommodates larger-sized plates and box-type workpieces. Featuring a robust cast iron gantry frame paired with high-rigidity components like square slides, it delivers stable performance for composite operations including milling, drilling, and boring. This makes it particularly suited for medium-to-heavy cutting demands in industries such as mold manufacturing, construction machinery, and aerospace components. Additionally, it is equipped with automatic tool changers (such as chain-type tool magazines) and high-efficiency cooling systems (such as central water supply), balancing machining efficiency with precision stability. This versatile gantry equipment effectively combines “processing dimensions” with “process compatibility.”

Production Workshop

Our production facility is a modern smart manufacturing workshop integrating precision machining, specialized assembly and debugging, stringent quality control, and efficient logistics, with an annual production capacity exceeding 800 machine tools. The workshop is divided into five functional zones: Precision Machining, Assembly and Debugging, Welding and Structural Manufacturing, Quality Inspection, and Spare Parts Storage & Logistics. It is equipped with advanced machinery including five-axis gantry machining centers, coordinate measuring machines, and robotic welding arms. Standardized management processes are implemented, encompassing 5S workplace management and the ISO 14001 Environmental Management System. All processes adhere to high-precision standards (e.g., IT5 machining accuracy, Ra 0.4μm surface roughness for critical components) and rigorous quality inspection procedures (all parts undergo three rounds of inspection). The logistics zone adjacent to Qingdao Port ensures efficient maritime delivery to global customers. This layout not only guarantees stable product quality and sufficient production capacity but also demonstrates our firm commitment as a modern manufacturing enterprise to clean production and social responsibility.

Manufacturing Process

The CNC machining process starts with creating a G-code program based on the workpiece’s 3D model, defining cutting paths, speeds, and tool changes. The program is uploaded to the CNC system, which interprets instructions to control the spindle, feed axes, and tool turret. After clamping the workpiece securely with a chuck, the machine initiates automatic machining—executing turning, milling, drilling, or threading as programmed. During operation, real-time monitoring ensures precision, with coolant and chip removal systems maintaining stability. Once completed, the workpiece is inspected for accuracy, and the program is saved for future batch production.

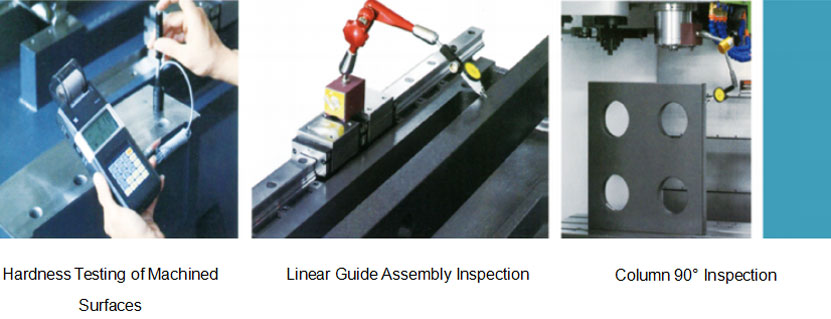

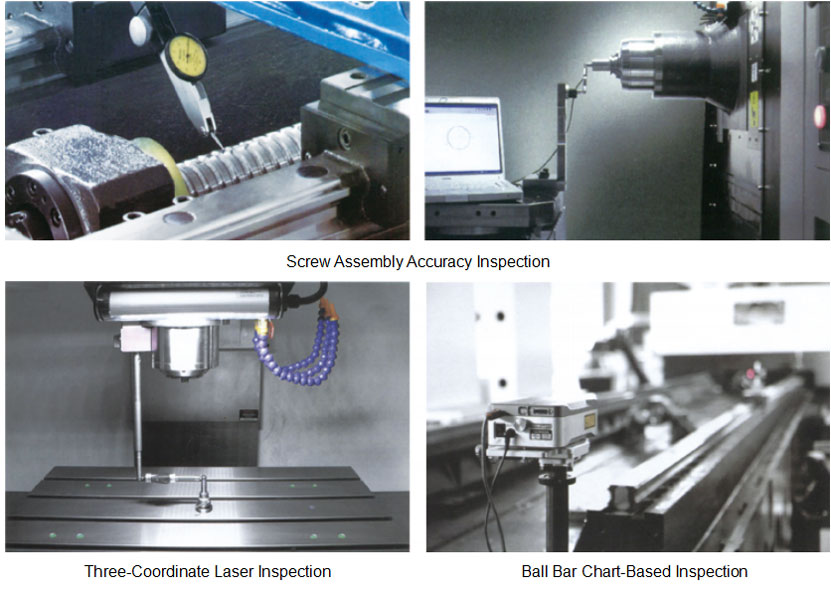

Multi-Layer Process Inspection

Laser Interferometer (Accuracy Calibration), Ball Bar (Circularity Calibration), Spindle/Motor Dynamic Balancing, Hardness Testing, Noise Testing, Machine Tool Geometric Accuracy Inspection, Lead Screw/Guide Rail Precision Inspection, Tool Changer/Machining Inspection.

Packing and Shipping

After production is completed, our equipment is packed in customized solid wood fumigated crates, ensuring a tight, secure, and reliable package. Shock-absorbing foam and steel reinforcements are used inside to control any movement of the machine’s core components to within millimeter-level precision during transportation. From packaging and loading to warehousing and shipment, we extend the same strict standards we apply to machining accuracy to every stage of logistics. Because the true value of a machine tool lies not only in its processing capability, but also in our commitment to “zero-loss” delivery from shipment to commissioning. Choosing us means choosing safe, reliable transportation and full responsibility at every step of the logistics process.

FAQ

Q:Where is your factory located? Can we visit it?

A: Our factory is located in Qingdao City, Shandong Province, China. We warmly welcome you to visit us.

Q: What is your average delivery time?

A: Generally, it is 5-10 days if the goods are in stock, and no stock basis depends on your quantity.

Q: What is the MOQ (Minimum Order Quantity)?

A: 1 set.

Q: What is your warranty situation?

A: The warranty period is one year. During the warranty period, if parts are damaged due to non-human factors, we will send new replacement parts free of charge.

Q: What are the payment terms?

A: T/T, 30% initial payment upon order, 70% balance payment before shipment.