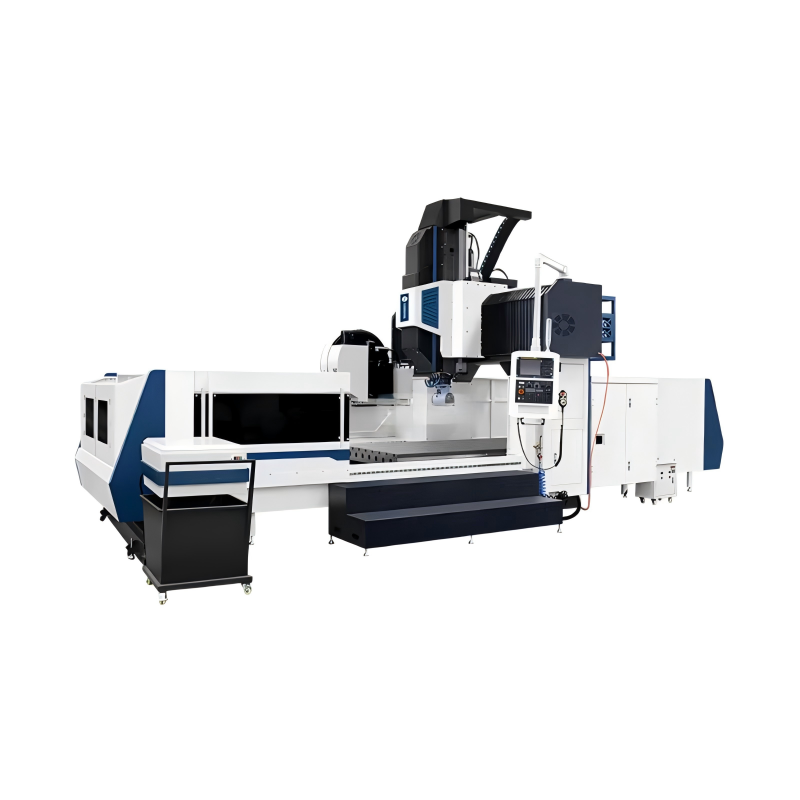

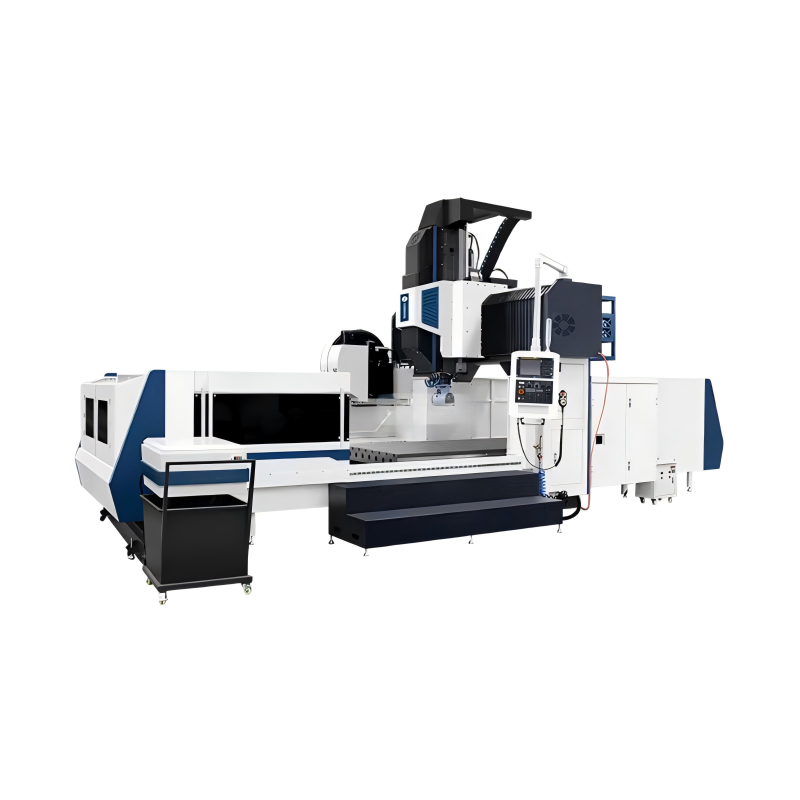

Versatile GMC2520 Fixed Beam CNC Center for Large Projects

Travel: X-axis 2500mm, Y-axis 2000mm, Z-axis 850mm

Work Table: Dimensions 2500×1700mm, Load Capacity 6000kg

Spindle: Maximum Speed 6000rpm, Motor Power 18.5/22kW

Travel Speed: XY-axis rapid traverse 10/10.8m/min

Machine Dimensions: Length 6800mm, Width 4600mm, Height 4500mm, Weight 23000kg

- Overview

- Recommended Products

Product Parameters

MachineType | Unit | GMC2520 |

X axis travel | mm | 2500 |

Y axis travel | mm | 2000 |

Z axis travel | mm | 850 |

Distance from spindle nose to worktable surface | mm | 200-1050 |

Gantry door width | mm | 2000 |

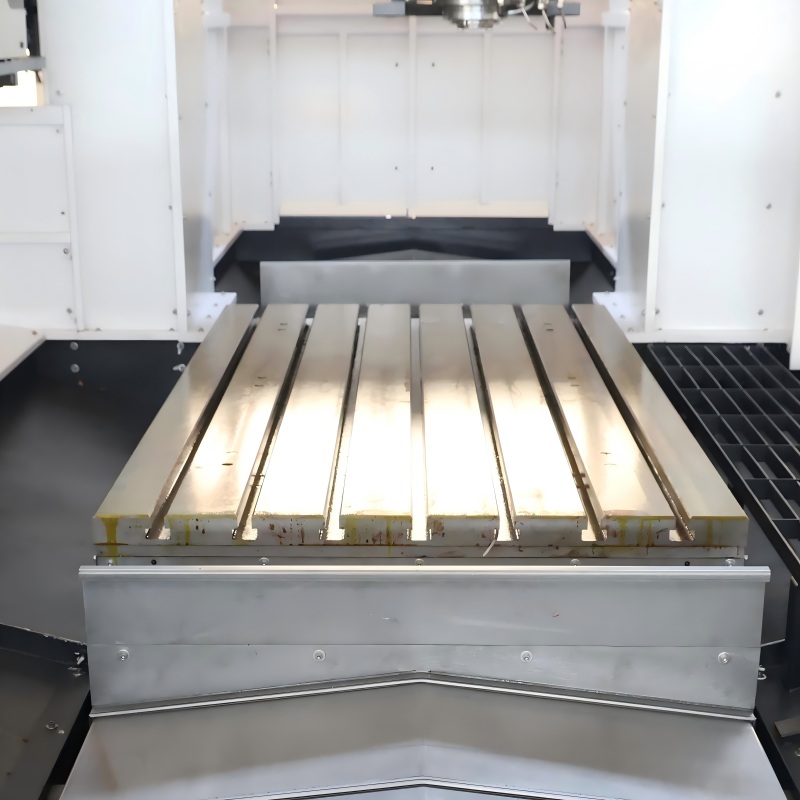

Worktable | ||

Table size(X axis) | mm | 2500 |

Table size(Y axis) | mm | 1700 |

T-slot | mm | 9-22-185 |

Max.table loading capacity | kg | 6000 |

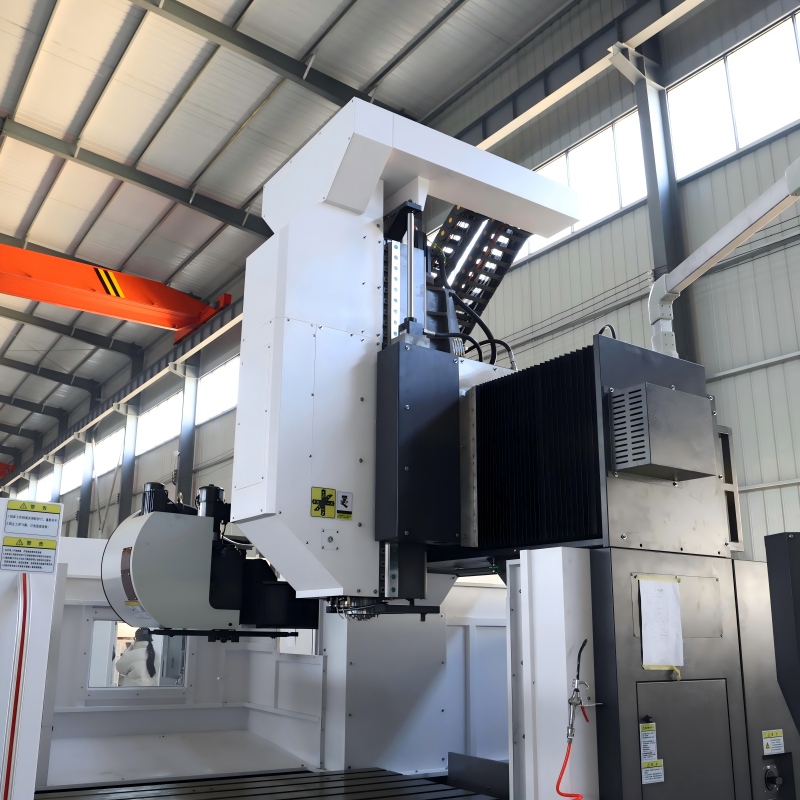

Spindle | ||

Spindle speed(belt type) | rpm | 6000 |

Spindle motor | kW | 18.5/22 |

Spindle bore taper | BT50 | |

Feed | ||

Three axis motors | Three-axis direct connection | |

XYZ axis rapid movement | m/min | 10.10.8 |

Tool magazine | ||

Tool Magazine Capacity | pcs | 24-position Arm-type |

Machine size | ||

Machine length | mm | 6800 |

Machine width | mm | 4600 |

Machine height | mm | 4500 |

Machine weight | kg | 23000 |

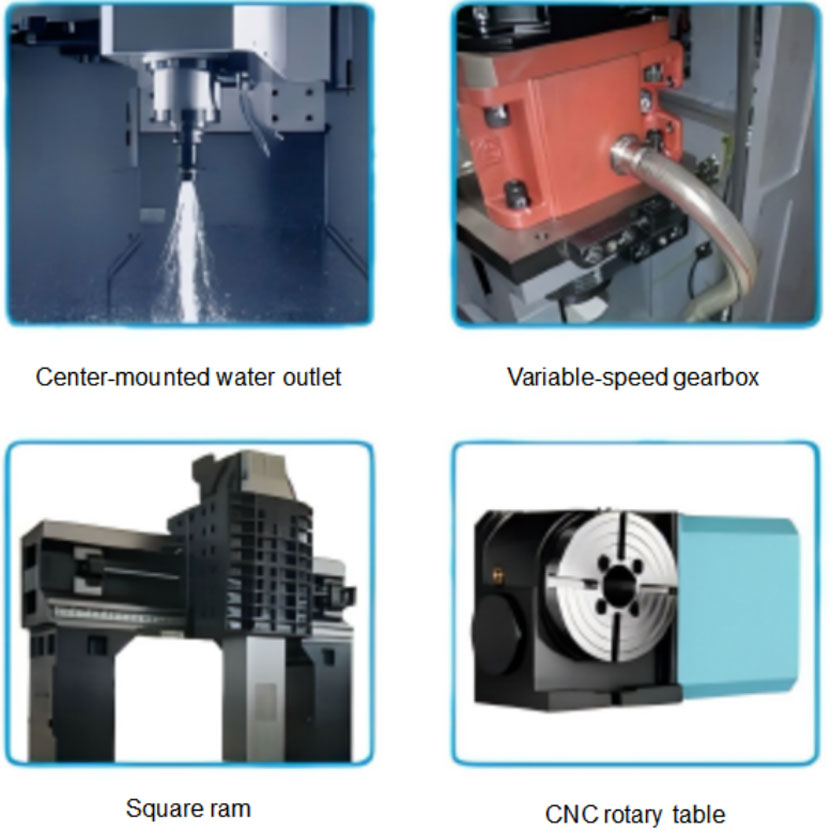

Key Components

Optional Configuration

Standard Configuration

KND 2000MF

BT50 Spindle

Dual Helical Chip Conveyor

Three-Axis Roller

Chain-Plate Chip Conveyor

24-Tool Disc Tool Magazin

Optional Configuration

Imported Variable Speed Gearbox

Spindle Center Coolant Supply

Spindle Oil Cooler

CNC Tool Post

Various Angle Milling Heads

Full-Chain Tool Magazine

Features

1. The worktable area is 1700 × 2500 mm, with a load capacity of 6 tons, suitable for processing large molds and heavy parts.

2. Super large processing capacity: With a 2500 mm X-axis travel, it offers a wide processing range and can complete multi-process machining of large workpieces in a single setup.

3. BT50 spindle bore taper, 6000 r/min spindle speed, suitable for both rough and finish machining, ideal for heavy cutting of steel parts and high-speed machining of aluminum alloys.

4. The machine weighs 23 tons and features an overall cast iron structure, providing excellent vibration resistance.

Application Areas

1. Automotive mold manufacturing: Used for processing large body panel molds, stamping dies, and plastic injection mold bases.

2. Machining of ship steel structure connectors and large hull components.

3. Machining of wind turbine gearbox housings, large generator bases, and energy machinery parts.

4. Machining of aluminum alloy wing connectors, aerospace structural components, and complex curved surface parts.

Processing Cases

The gantry machining series accommodates larger-sized plates and box-type workpieces. Featuring a robust cast iron gantry frame paired with high-rigidity components like square slides, it delivers stable performance for composite operations including milling, drilling, and boring. This makes it particularly suited for medium-to-heavy cutting demands in industries such as mold manufacturing, construction machinery, and aerospace components. Additionally, it is equipped with automatic tool changers (such as chain-type tool magazines) and high-efficiency cooling systems (such as central water supply), balancing machining efficiency with precision stability. This versatile gantry equipment effectively combines “processing dimensions” with “process compatibility.”

Manufacturing Process

The CNC machining process starts with creating a G-code program based on the workpiece’s 3D model, defining cutting paths, speeds, and tool changes. The program is uploaded to the CNC system, which interprets instructions to control the spindle, feed axes, and tool turret. After clamping the workpiece securely with a chuck, the machine initiates automatic machining—executing turning, milling, drilling, or threading as programmed. During operation, real-time monitoring ensures precision, with coolant and chip removal systems maintaining stability. Once completed, the workpiece is inspected for accuracy, and the program is saved for future batch production.

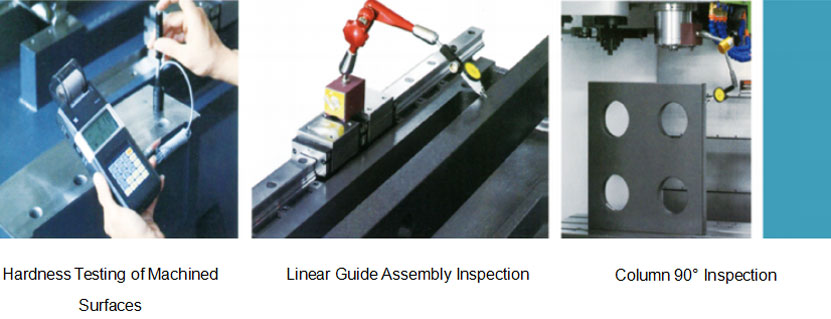

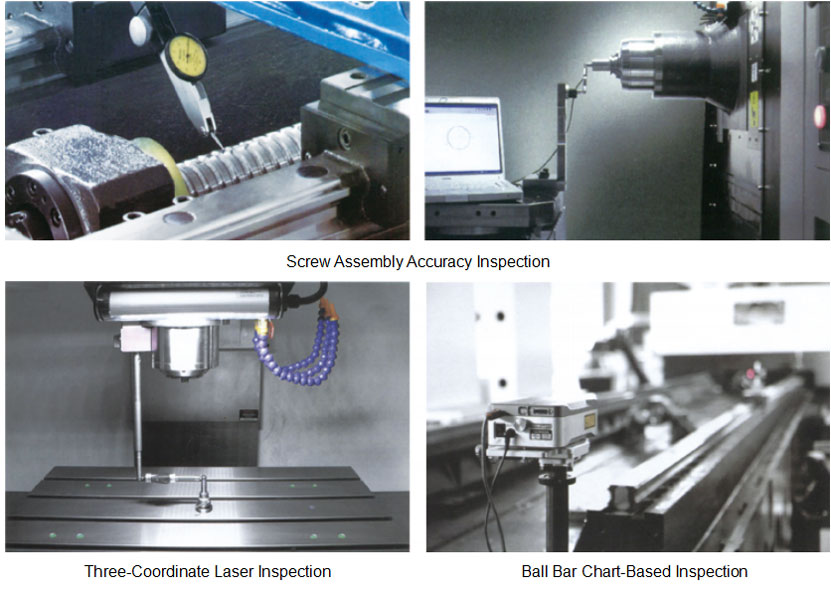

Multi-Layer Process Inspection

Laser Interferometer (Accuracy Calibration), Ball Bar (Circularity Calibration), Spindle/Motor Dynamic Balancing, Hardness Testing, Noise Testing, Machine Tool Geometric Accuracy Inspection, Lead Screw/Guide Rail Precision Inspection, Tool Changer/Machining Inspection.

Packing and Shipping

After production is completed, our equipment is packed in customized solid wood fumigated crates, ensuring a tight, secure, and reliable package. Shock-absorbing foam and steel reinforcements are used inside to control any movement of the machine’s core components to within millimeter-level precision during transportation. From packaging and loading to warehousing and shipment, we extend the same strict standards we apply to machining accuracy to every stage of logistics. Because the true value of a machine tool lies not only in its processing capability, but also in our commitment to “zero-loss” delivery from shipment to commissioning. Choosing us means choosing safe, reliable transportation and full responsibility at every step of the logistics process.

FAQ

Q: Why choose us?

A. We are a manufacturer; we have manufactured machine tools for over 20 years.

B. Reliable Quality Assurance System;

C. Cutting-Edge Computer-Controlled CNC Machines;

D. Bespoke Solutions from Highly Experienced Specialists;

E. Customization and OEM Available for Specific Application;

F. Extensive Inventory of Spare Parts and Accessories;

G. Well-Developed Worldwide Marketing Network;

H. Efficient After-Sale Service System

Q: What is your payment term?

A: 30% TT deposit, 70% balance T/T before shipping.

Q: Can we print our logo on your products?

A: Yes, we offer OEM/ODM service, and we support the customized logo, size, package, etc.

Q: What is your main market?

A: North America, South America, Eastern Europe, Western Europe, Southeast Asia, Africa, Oceania, the Middle East, Eastern Asia.

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.