Common Problem Solutions

Q: What should be done before first use?

A: Check lubrication, coolant, tool installation, and limit settings.

Q: How to manually move axes?

A: Switch to manual mode and use the axis selection key and direction keys to move.

Q: Servo system and drive troubleshooting

A: Common servo system faults include excessive position deviation, motor vibration, and system instability. For position deviation, possible causes include damaged encoders, poor feedback system connections, or improper drive parameter settings. Diagnosis involves inspecting motor and encoder connections to ensure no loose wiring, while verifying encoder readings are accurate. If drive parameter issues are confirmed, adjust settings according to the machine tool manual.

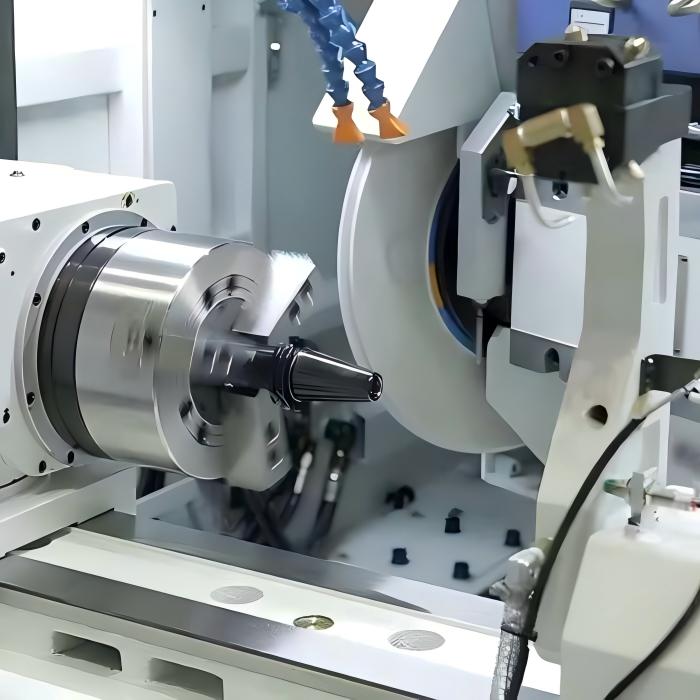

Adjustment and Calibration of Machine Tool Accuracy Issues

The accuracy of a CNC machine tool directly affects the quality of the machined workpiece. Accuracy issues typically involve the geometric accuracy, positioning accuracy, and repeat positioning accuracy of the machine tool. Geometric accuracy refers to the precision of the relative positions between the machine's moving components. Positioning accuracy is the machine's ability to move to a specified position according to program instructions. Repeat positioning accuracy is the precision with which the machine returns to the same position repeatedly.

Resolving machine tool accuracy issues usually requires meticulous adjustment and calibration. The adjustment process may involve recalibrating the straightness, levelness, and perpendicularity of the guide rails, as well as adjusting the backlash of the ball screws and racks. The calibration process may require using standard measuring tools and laser interferometers to test the machine's positioning and repeat positioning accuracy. For example, if repeat positioning accuracy is found to be substandard, it may be necessary to adjust the ball screw backlash or correct the calibration values of the feedback system.

The Importance of Regular Inspection and Maintenance

Preventive maintenance is a maintenance strategy that takes action before failures occur. Its purpose is to prevent faults through regular inspections and upkeep. For CNC machine tools, regular maintenance can help identify potential issues and repair them in a timely manner, thereby avoiding unexpected downtime and production delays.

Preventive maintenance includes cleaning guide rails, inspecting and replacing worn components, lubrication and oiling, calibrating and adjusting accuracy, etc. Take regular guide rail cleaning as an example: the accumulation of dirt and metal debris will accelerate machine wear and reduce machining accuracy. Regular cleaning work can extend the service life of the machine tool.