Installation and Commissioning

Equipment Calibration Service Process with Remote Video Guidance

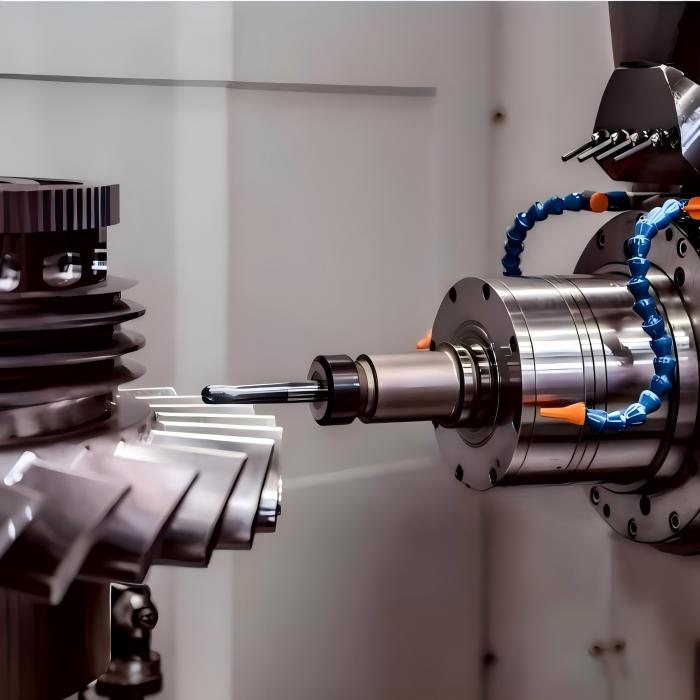

Remote operation and maintenance of CNC machine tools is an effective means to ensure processing quality and safe, reliable operation.

First, the architectural framework of the series of standards is analyzed.

Second, the hierarchical structure of CNC machine tool remote operation and maintenance is examined from the perspectives of the remote operation and maintenance service platform and its functional capabilities.

Third, functional aspects such as status information acquisition, health status assessment, fault diagnosis, and condition prediction are addressed.

Real-time Monitoring: Enables second-level data collection and visualization of all CNC machine tool operating statuses and core parameters, with data accuracy ≥99%.

Anomaly Alerts: Implements tiered alerts for abnormal data such as vibration, temperature, and load, achieving alert accuracy ≥90% and reducing fault response time to within 10 minutes.

Predictive Maintenance: Utilizes big data and AI algorithms to forecast the lifespan of critical components like bearings and spindles, transforming scheduled maintenance into predictive maintenance. This reduces equipment failure rates by over 15%.

Data Integration: Interfaces with MES and ERP systems to deeply integrate equipment data with production planning and energy consumption management, enhancing overall workshop operational efficiency.

Secure and Controllable: Ensures end-to-end security for data collection, transmission, and storage, meeting industrial data confidentiality and compliance requirements.