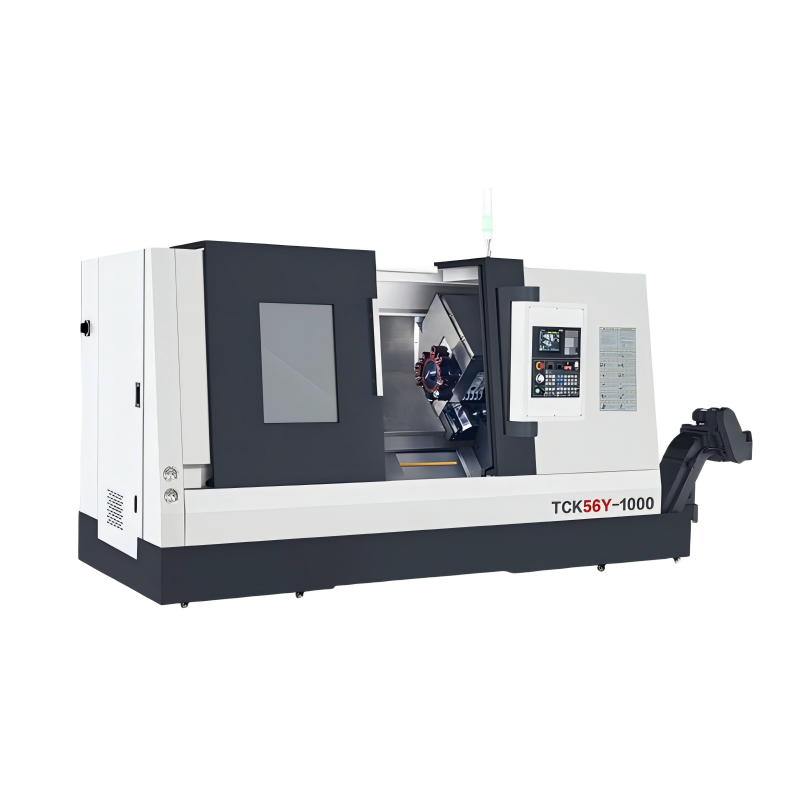

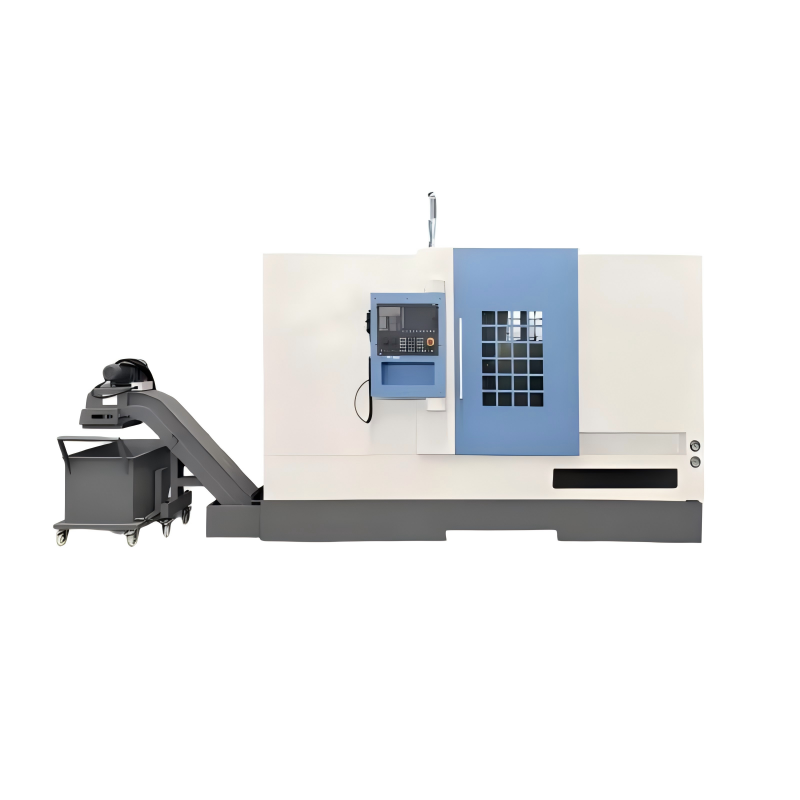

High-EfficiencyTCK66Y Slant Bed CNC Turning Lathe Machine

TCK66Y Wider Processing Range:

The maximum swing diameter over the bed reaches φ700mm, and the maximum machining length supports 1000/1500/2000/3000/4000mm. Bar stock machining capacity is φ75mm (φ90mm optional), covering extra-large shaft and disc-shaped parts.

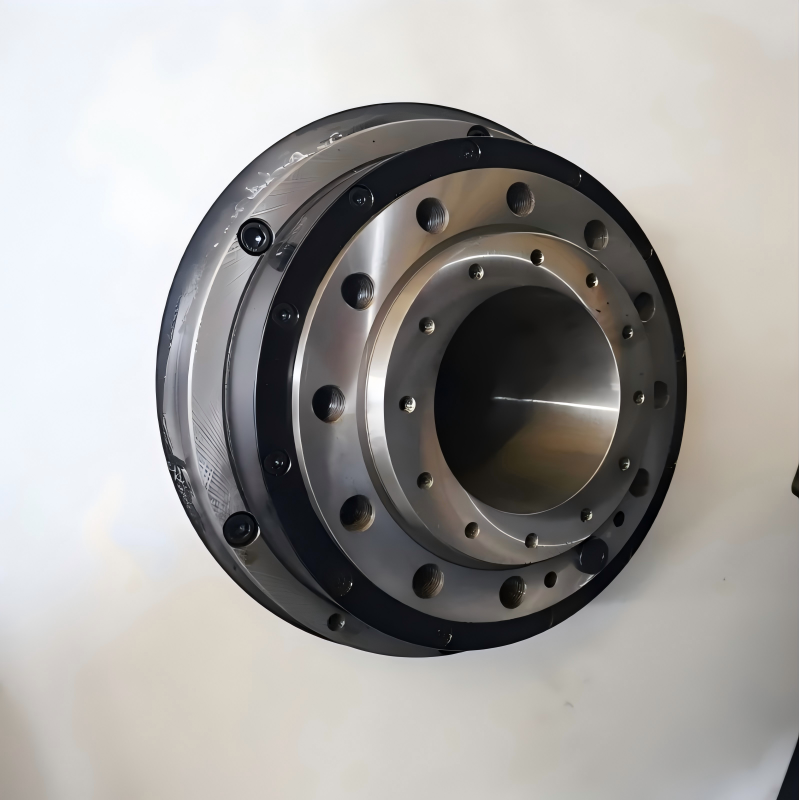

Spindle end type A2-8 (A2-11 optional), through-hole φ86/104mm, main motor power 15kW, equipped with hydraulic chuck/tailstock, strong stability for heavy-duty cutting; hybrid design of linear and hard rails, X/Y/Z axis rapid traverse speed up to 12/12/15m/min.

- Overview

- Recommended Products

TCK66Y CNC Lathe Machine Specifications

SPECIFICATIONS | Unit | TCK66Y |

Max.swing over bed | mm | 700 |

Max.swing over slide | mm | 500 |

Max.processing length | mm | 1000/1500/2000/3000/4000 |

Max.bar capacity | mm | 75(optional 90) |

Max.processing diameter (plate) | mm | 500 |

Spindle nose type | A2-8(optional A2-11) | |

Spindle bore | mm | Φ86/Φ104 |

Spindle speed range | min | 3500(optional 1500) |

Spindle shift mode | Stepless | |

Spindle motor power | kw | 15 |

Chuck type | Hydaulic | |

Chuck size | Inch | 12 |

X axis rapid traverse | m/min | 12 |

Z axis rapid traverse | m/min | 15 |

Y axis rapid traverse | m/min | 12 |

X axis servo motor torque | N.m | 15 |

Z axis servo motor torque | N.m | 15 |

Y axis servo motor torque | N.m | 12 |

X axis travel | mm | 280/330/430 |

Z axis travel | mm | 1650/2150/3150 |

Y axis travel | mm | ±50 |

Guide way type | Linear rail | |

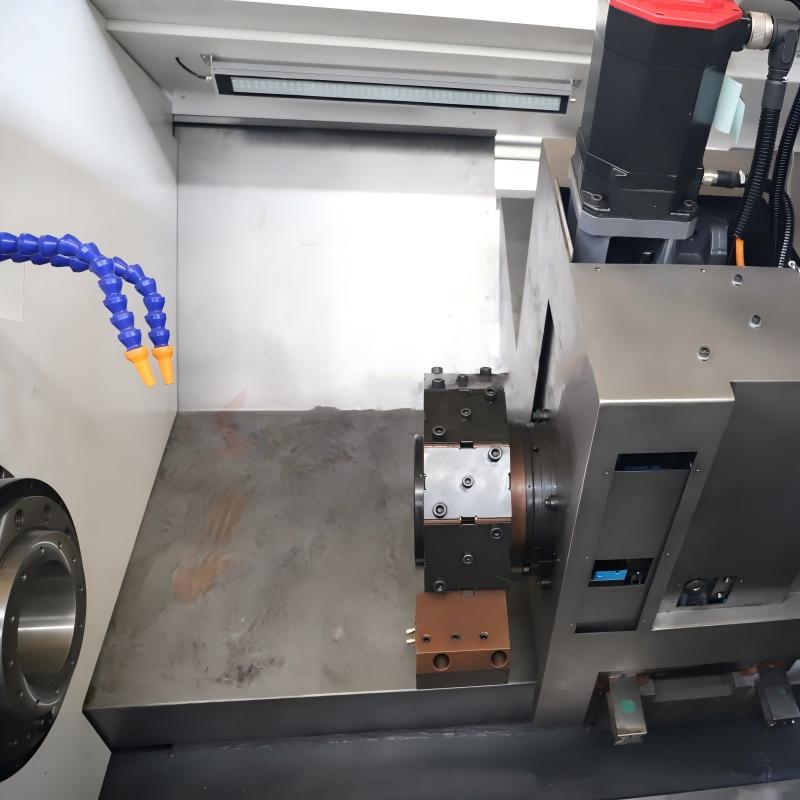

Tool post type | 12-statian power turet | |

knife holder model | BMT55 |

Key Components

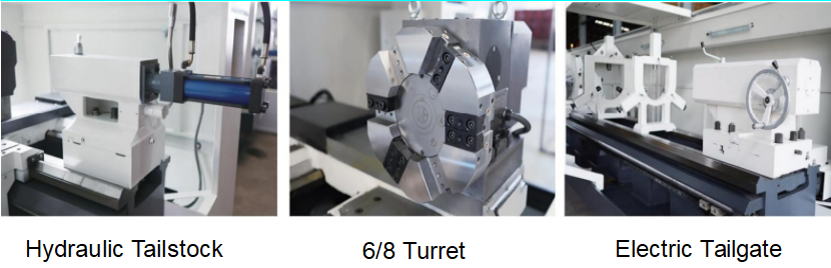

Optional Configuration

Fanuc, Siemens, GSK,KND, SYNTEC and other CNC system, living tool turret, Y axis to achieve turning and milling complex function, tool setting gauge, workpiece measuring tools, workpiece collector chip removal machine, automatic door, safety door, oil mist collector, hydraulic center frame, tailstock programmable, double spindle.

Features

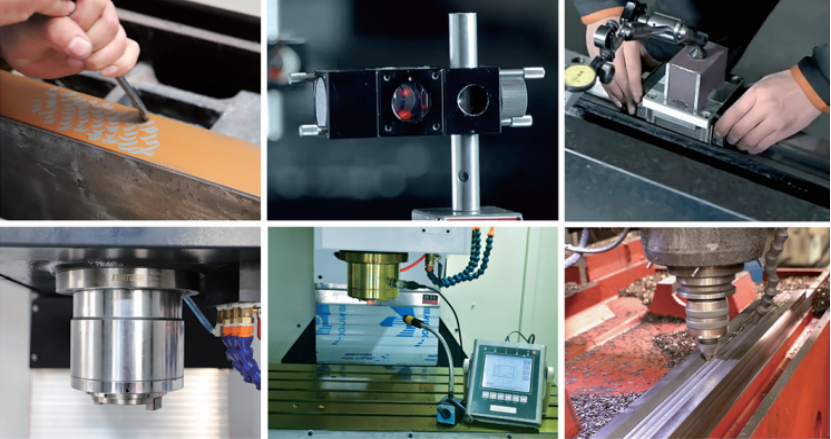

Adopting high-speed, high-precision and high-rigidity spindle unit, the original servo spindle motor can achieve higher spindle speed. The spindle unit is assembled in a constant temperature room, and after assembly, it is run-in at a constant temperature for 72 hours continuously. After being installed on the machine, it is tested for another 72 hours continuously to ensure the reliability and durability of high-speed and high-precision performance;

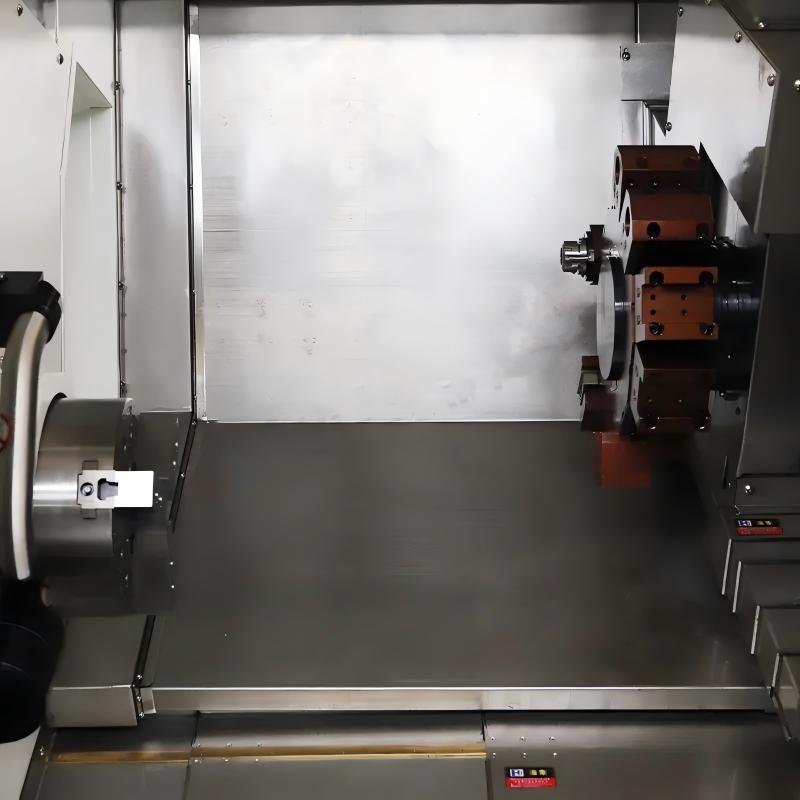

The standard configuration adopts BMY65 heavy-duty power turret, which has fast tool change speed and high positioning accuracy. The Y-axis adopts a rectangular track to ensure the rigidity requirements during the cutting process;

The X and Z direction feed adopts a servo motor directly connected to the lead screw through a large torque and low inertia elastic coupling. The lead screw support adopts a pre-stretching structure, which can eliminate the transmission backlash and pre-compensate the influence of thermal deformation on the accuracy during longterm operation of the machine tool, ensuring positioning accuracy and repeat positioning accuracy;

Advanced centralized automatic lubrication device is adopted, and the automatic intermittent lubrication with timing and quantity is adopted to make the machine tool work more stable and reliable;

The machine tool protection adopts a full protection design, which is highly pleasant, beautiful and unique, reliable in waterproofing and chip prevention, and easy to maintain;

The tailstock adopts the transmission mode of gear + reducer for movement; the tailstock body is locked by hydraulic method, which is more convenient and quick to operate; the tailstock sleeve is also operated by hydraulically tightening the workpiece.

Application Areas

The TCK66Y CNC turning-milling composite machine focuses on the efficient heavy-duty machining of medium-to-large complex precision parts, catering to equipment manufacturing industries with stringent requirements for machining dimensions, rigidity, and process integration.

1. Heavy-duty Automotive and Commercial Vehicle Component Manufacturing

Capable of machining medium-to-large components such as heavy-duty truck axle shafts, transmission output shafts, and clutch housings. Its substantial spindle power and rigid structure enable efficient cutting of difficult-to-machine materials like alloy steel and cast steel. The interpolated Y-axis, combined with a power turret, allows simultaneous turning, milling, drilling, and tapping operations in a single setup, minimizing clamping errors.

2. Core Components for Construction Machinery

Suitable for heavy-duty parts like excavator slewing bearings, loader hydraulic cylinder piston rods, and crane drum shafts. The high-torque power turret handles complex operations such as deep-hole drilling and heavy-load milling. Tailstock support structures effectively suppress vibration during long shaft machining, ensuring precision and surface quality.

3. Mining Machinery Component Production

Processes wear-resistant parts like crusher eccentric shafts, conveyor drum shafts, and mining hydraulic support valve blocks. The high-rigidity monolithic cast bed offers superior deformation resistance, withstanding continuous heavy-duty cutting to meet mining machinery components' dual demands for durability and precision.

4. Wind Power Equipment Critical Component Machining

Processes medium-to-large structural components like wind turbine gearbox drive shafts, yaw system connectors, and hub flanges. Its large swivel diameter accommodates oversized disc and shaft parts, while four-axis interpolation enables precision machining of complex irregular grooves and end-face cams.

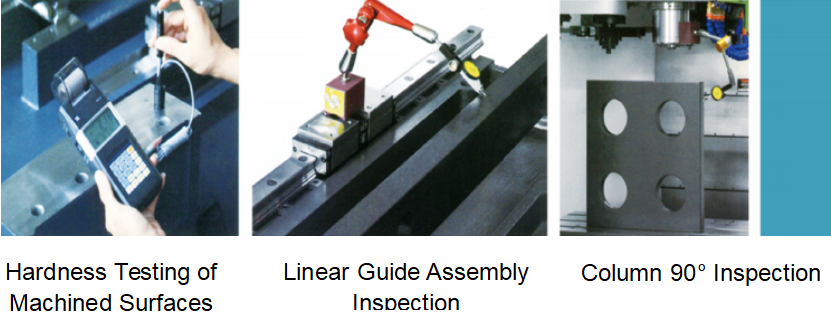

Manufacturing Process

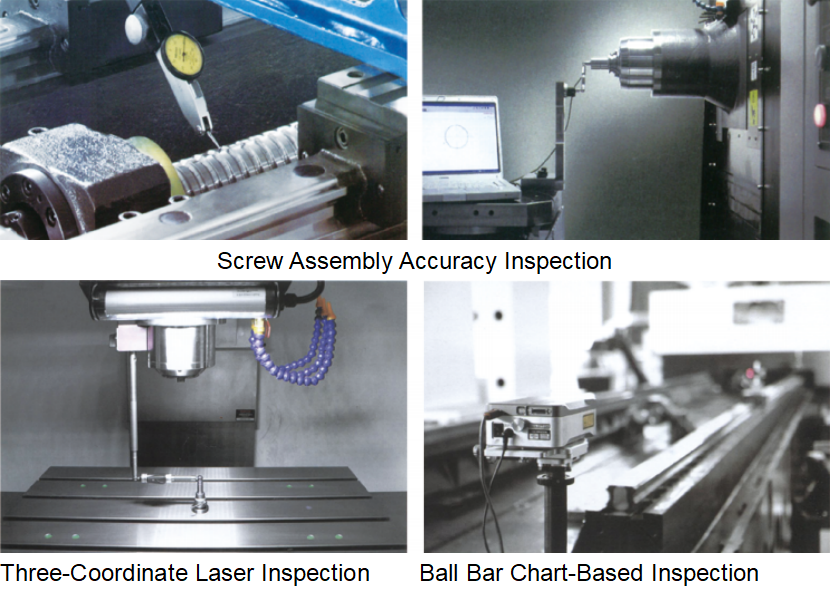

Multi-Layer Process Inspection

Laser Interferometer (Accuracy Calibration), Ball Bar (Circularity Calibration), Spindle/Motor Dynamic Balancing, Hardness Testing, Noise Testing, Machine Tool Geometric Accuracy Inspection, Lead Screw/Guide Rail Precision Inspection, Tool Changer/Machining Inspection.

Packing and Shipping

After production is completed, our equipment is packed in customized solid wood fumigated crates, ensuring a tight, secure, and reliable package. Shock-absorbing foam and steel reinforcements are used inside to control any movement of the machine’s core components to within millimeter-level precision during transportation. From packaging and loading to warehousing and shipment, we extend the same strict standards we apply to machining accuracy to every stage of logistics. Because the true value of a machine tool lies not only in its processing capability, but also in our commitment to “zero-loss” delivery from shipment to commissioning. Choosing us means choosing safe, reliable transportation and full responsibility at every step of the logistics process.

FAQ

Q: Why choose us?

A. We are a manufacturer; we have manufactured machine tools for over 20 years.

B. Reliable Quality Assurance System;

C. Cutting-Edge Computer-Controlled CNC Machines;

D. Bespoke Solutions from Highly Experienced Specialists;

E. Customization and OEM Available for Specific Application;

F. Extensive Inventory of Spare Parts and Accessories;

G. Well-Developed Worldwide Marketing Network;

H. Efficient After-Sale Service System

Q: What is your payment term?

A: 30% TT deposit, 70% balance T/T before shipping.

Q: Can we print our logo on your products?

A: Yes, we offer OEM/ODM service, and we support the customized logo, size, package, etc.

Q: What is your main market?

A: North America, South America, Eastern Europe, Western Europe, Southeast Asia, Africa, Oceania, the Middle East, Eastern Asia,

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.