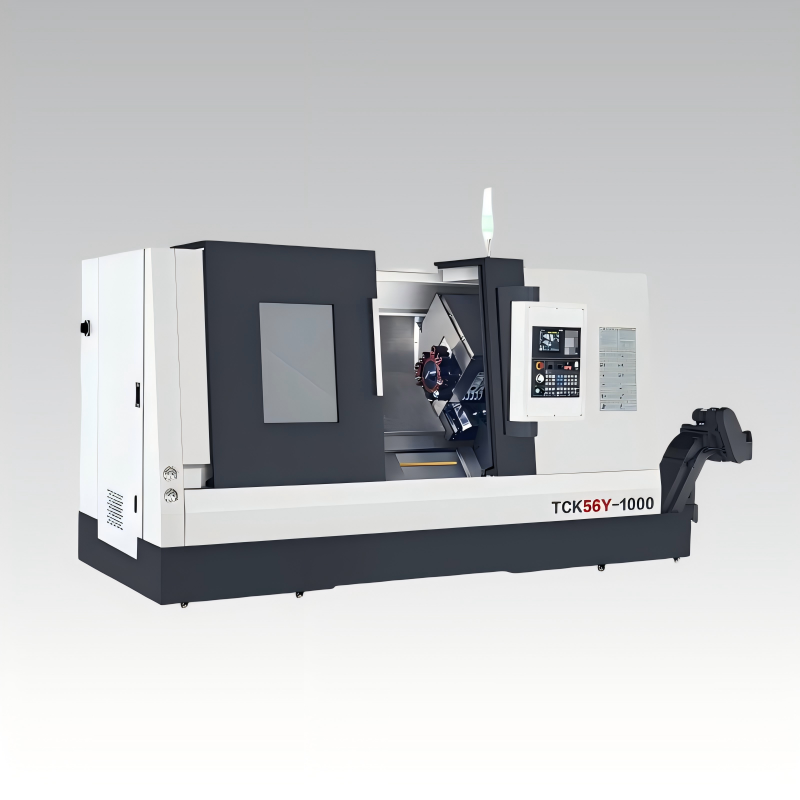

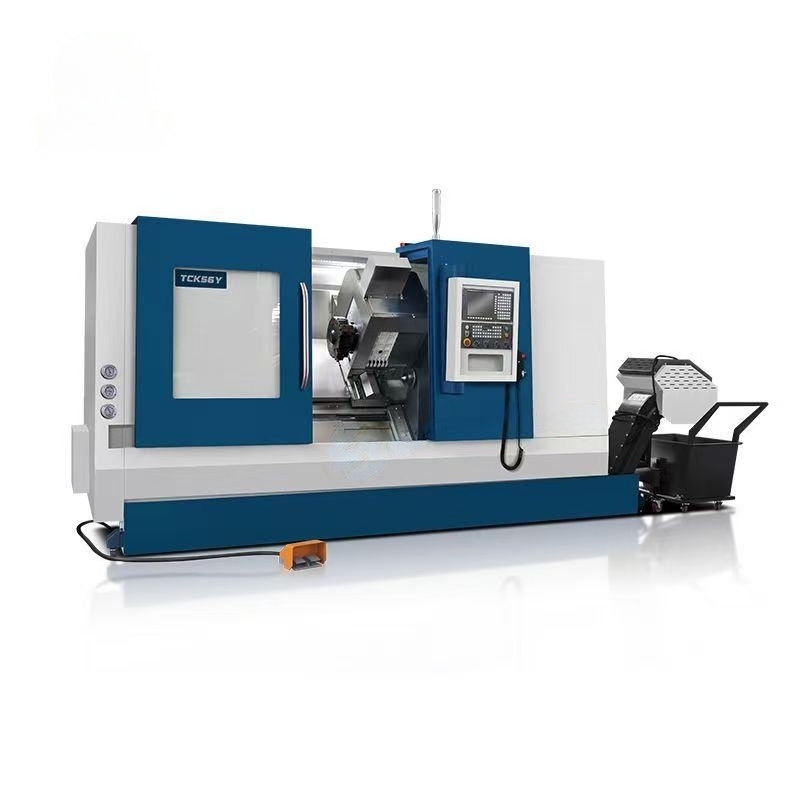

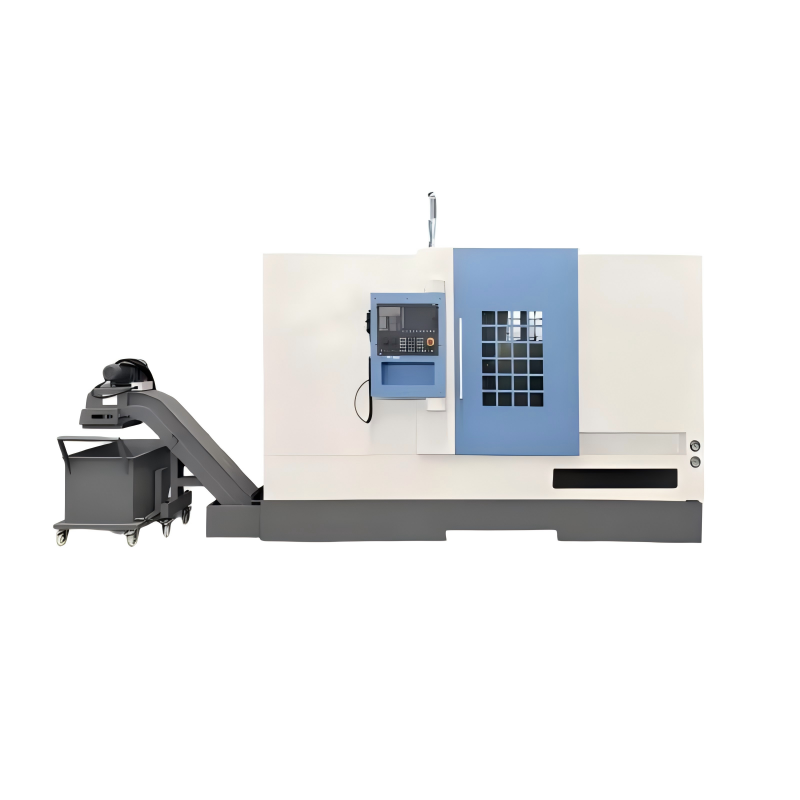

TCK56Y Turning Center Metal Slant Bed CNC Lathe High Precision

Strong Machining Capabilities:

TCK56Y the maximum swing diameter of the bed reaches φ650mm, and the maximum machining length supports 500/1000/1500mm. Bar stock machining capacity is φ52mm (φ75mm optional), covering medium and large shaft and disc-shaped parts.

High-Precision Configuration:

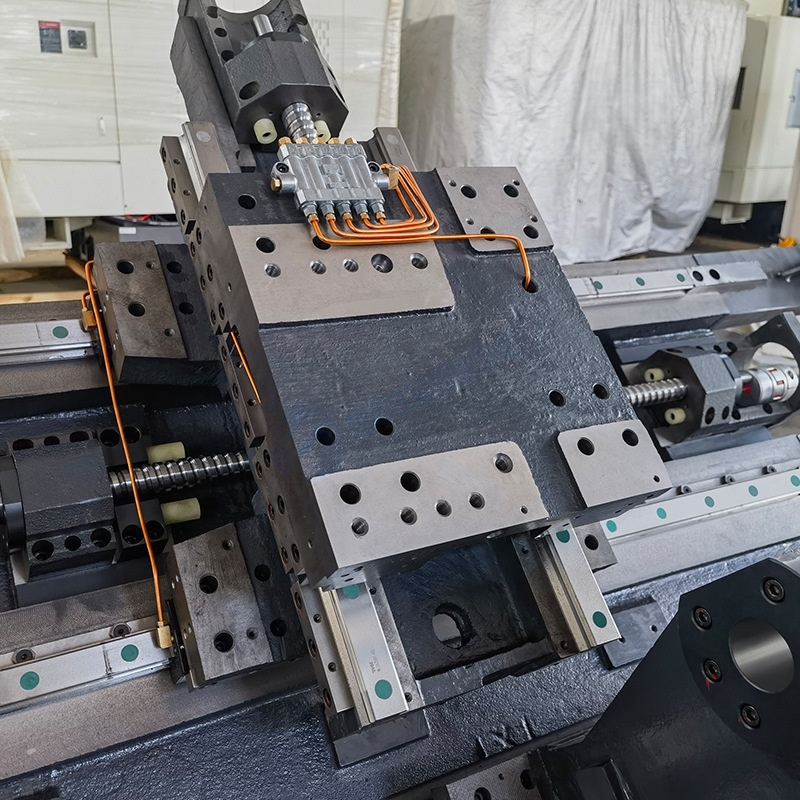

Adopting a hybrid design of linear and hard rails, the X/Y/Z axes have rapid traverse speeds of up to 15/12/15 m/min, ensuring high positioning accuracy; the 12-station power turret allows for fast tool changes, suitable for multi-process continuous machining.

High-Rigidity Structure:

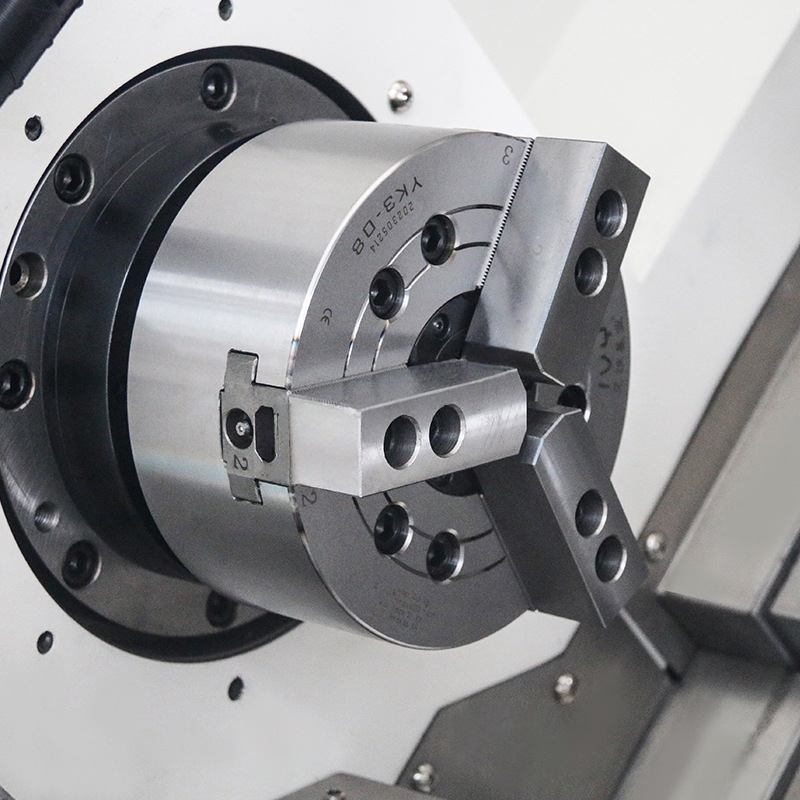

The spindle through-hole is φ66/86mm, with a 15kW main motor, and is equipped with a hydraulic chuck/tailstock, providing strong stability for heavy-duty cutting; the 45° slanted bed design ensures smooth chip removal and good vibration resistance.

- Overview

- Recommended Products

Specifications

SPECIFICATIONS | Unit | TCK56Y |

Max.swing over bed | mm | 650 |

Max.swing over slide | mm | 500 |

Max.processing length | mm | 500/1000/1500 |

Max.bar capacity | mm | 52(optional 75) |

Max.processing diameter (plate) | mm | 500 |

Spindle nose type | A2-6(optional A2-8) | |

Spindle bore | mm | Φ66/φ86 |

Spindle speed range | min | 4000(optional 3500) |

Spindle shift mode | Stepless | |

Spindle motor power | kw | 15 |

Chuck type | Hydraulic | |

Chuck size | Inch | 12 |

X axis rapid traverse | m/min | 12 |

Z axis rapid traverse | m/min | 15 |

Y axis rapid traverse | m/min | 12 |

X axis servo motor torque | N.m | 15 |

Z axis servo motor torque | N.m | 15 |

Y axis servo motor torque | N.m | 12 |

X axis travel | mm | 280/330/430 |

Z axis travel | mm | 1650/2150/3150 |

Y axis travel | mm | ±45 |

Guide way type | Linear rail | |

Tool post type | 12-station power turret | |

knife holder model | BMT45 |

Key Components

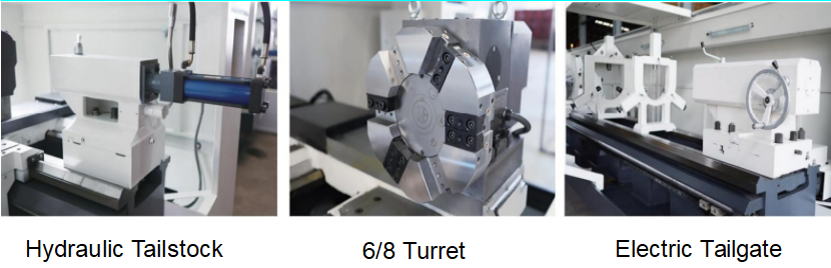

Optional Configuration

Fanuc, Siemens, GSK,KND, SYNTEC and other CNC system, living tool turret, Y axis to achieve turning and milling complex function, tool setting gauge, workpiece measuring tools, workpiece collector chip removal machine, automatic door, safety door, oil mist collector, hydraulic center frame, tailstock programmable, double spindle.

Advantages

Streamline Processes&Boost Efficiency

Turning-milling composite machining enables all or most machining operations to be completed in a single setup, significantly shortening the manufacturing process chain and markedly improving production efficiency.

Reduced Fixtures& Enhanced Precision

Fewer clamping operations eliminate cumulative errors caused by changing positioning references. Equipment-integrated in-process inspection capabilities improve machining accuracy.

Compact Footprint& Lower Investment

The shortened manufacturing process chain and reduced equipment requirements, along with fewer fixtures, smaller workshop space, and lower maintenance costs, effectively decrease overall investment, production operation, and management expe.

Application Areas

The TCK56Y CNC turning-milling composite machine focuses on multi-process integrated machining of medium-sized complex precision parts, catering to industries such as automotive, hydraulics, and general machinery that demand both precision and efficiency.

1. Automotive Components Industry

Capable of machining medium-sized parts such as automotive transmission intermediate shafts, steering system tie rod ball studs, and engine valve lifters. The interpolated Y-axis, combined with a power turret, enables simultaneous turning of outer diameters, milling keyways, and drilling radial holes in a single setup, ensuring dimensional consistency for mass production.

2. Hydraulic and Pneumatic Components Industry

Suitable for machining hydraulic pump rotors, cylinder barrel end caps, solenoid valve stems, and similar components. Four-axis interpolation enables precise processing of complex cavities and irregular surfaces, replacing traditional multi-machine division of labor to reduce part handling and clamping errors.

3. General Machinery & Hardware Manufacturing

Processes universal components like gearbox shafts, couplings, and precision fasteners. Its medium swivel diameter and spindle power accommodate cutting demands for carbon steel, stainless steel, and other materials, making it suitable for small-to-medium batch production of diverse parts.

4. Agricultural Machinery Components Manufacturing

Processes components like seeder drive shafts, harvester gearbox parts, and plant protection machinery hydraulic connectors. The high-rigidity machine body handles interrupted cutting conditions, while the tailstock support structure ensures stability during machining of slender shaft parts, preventing cutting deformation.

5. Medical Devices and Precision Instruments Industry

Suitable for machining stainless steel surgical instrument shafts, precision shaft sleeves for testing instruments, and similar components. High-precision positioning and low-vibration cutting characteristics meet the stringent surface finish and tolerance requirements of medical device parts.

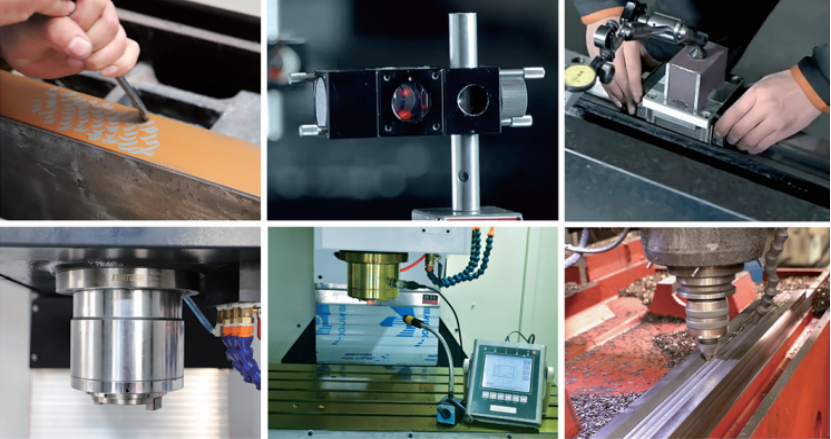

Manufacturing Process

The CNC machining process starts with creating a G-code program based on the workpiece’s 3D model, defining cutting paths, speeds, and tool changes. The program is uploaded to the CNC system, which interprets instructions to control the spindle, feed axes, and tool turret. After clamping the workpiece securely with a chuck, the machine initiates automatic machining—executing turning, milling, drilling, or threading as programmed. During operation, real-time monitoring ensures precision, with coolant and chip removal systems maintaining stability. Once completed, the workpiece is inspected for accuracy, and the program is saved for future batch production.

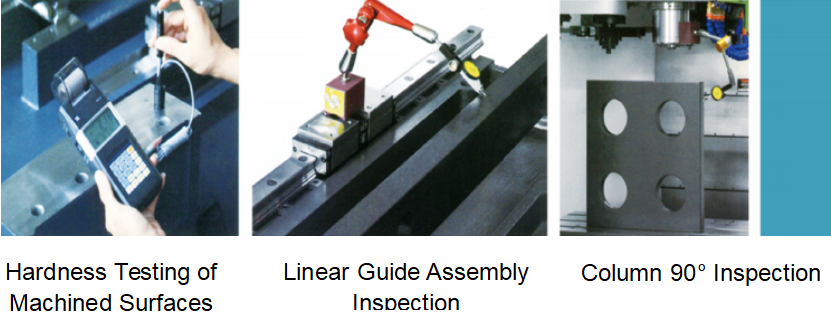

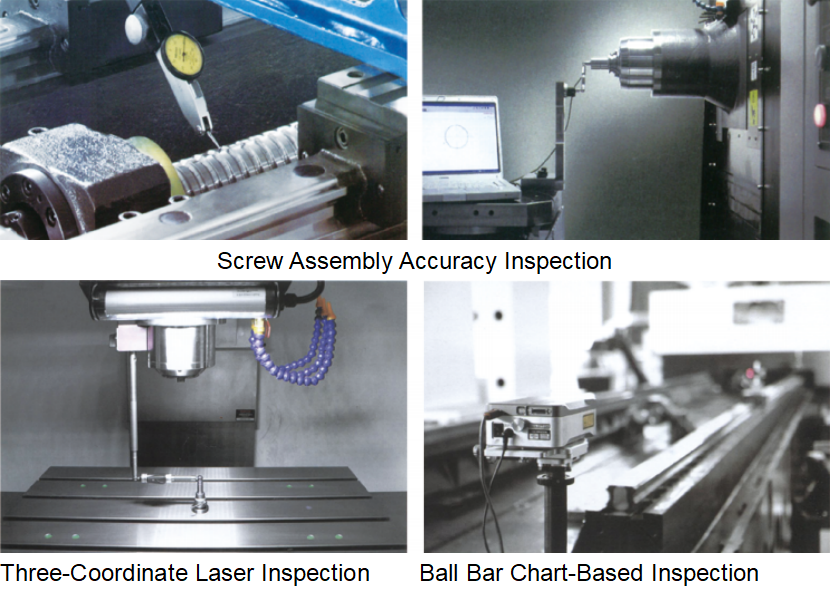

Multi-Layer Process Inspection

Laser Interferometer (Accuracy Calibration), Ball Bar (Circularity Calibration), Spindle/Motor Dynamic Balancing, Hardness Testing, Noise Testing, Machine Tool Geometric Accuracy Inspection, Lead Screw/Guide Rail Precision Inspection, Tool Changer/Machining Inspection

Packing and Shipping

After production is completed, our equipment is packed in customized solid wood fumigated crates, ensuring a tight, secure, and reliable package. Shock-absorbing foam and steel reinforcements are used inside to control any movement of the machine’s core components to within millimeter-level precision during transportation. From packaging and loading to warehousing and shipment, we extend the same strict standards we apply to machining accuracy to every stage of logistics. Because the true value of a machine tool lies not only in its processing capability, but also in our commitment to “zero-loss” delivery from shipment to commissioning. Choosing us means choosing safe, reliable transportation and full responsibility at every step of the logistics process.

FAQ

Q: Why choose us?

A. We are a manufacturer; we have manufactured machine tools for over 20 years.

B. Reliable Quality Assurance System;

C. Cutting-Edge Computer-Controlled CNC Machines;

D. Bespoke Solutions from Highly Experienced Specialists;

E. Customization and OEM Available for Specific Application;

F. Extensive Inventory of Spare Parts and Accessories;

G. Well-Developed Worldwide Marketing Network;

H. Efficient After-Sale Service System

Q: What is your payment term?

A: 30% TT deposit, 70% balance T/T before shipping.

Q: Can we print our logo on your products?

A: Yes, we offer OEM/ODM service, and we support the customized logo, size, package, etc.

Q: What is your main market?

A: North America, South America, Eastern Europe, Western Europe, Southeast Asia, Africa, Oceania, the Middle East, Eastern Asia.

Q: Can I get samples from your factory?

A: Yes, Samples can be provided.